How to Get Smells Out of Silicone Kitchenware: 10 Science-Backed Methods for a Fresh Kitchen

The most effective way to eliminate odors from silicone is through low-temperature heat, which forces the material's molecules to expand and release trapped oils. You pull out your favorite silicone spatula or Instant Pot sealing ring, only to realize it reeks of last week’s garlic curry or sour milk. Despite multiple cycles in the dishwasher, that pungent, stubborn odor refuses to budge.

Using "stinky" silicone isn't just unpleasant; it ruins the flavor profile of your current meal. Imagine baking delicate vanilla cupcakes only for them to carry a faint, metallic hint of fermented onions. For those using silicone in high-heat cooking, these trapped oils can become a breeding ground for persistent, unappetizing scents.

Getting smells out of silicone requires understanding the material's chemistry. In this guide, we provide a definitive roadmap on how to get smells out of silicone using heat, natural bases, and professional-grade maintenance tips to restore your tools to a factory-fresh state.

Why does silicone kitchenware absorb strong odors?

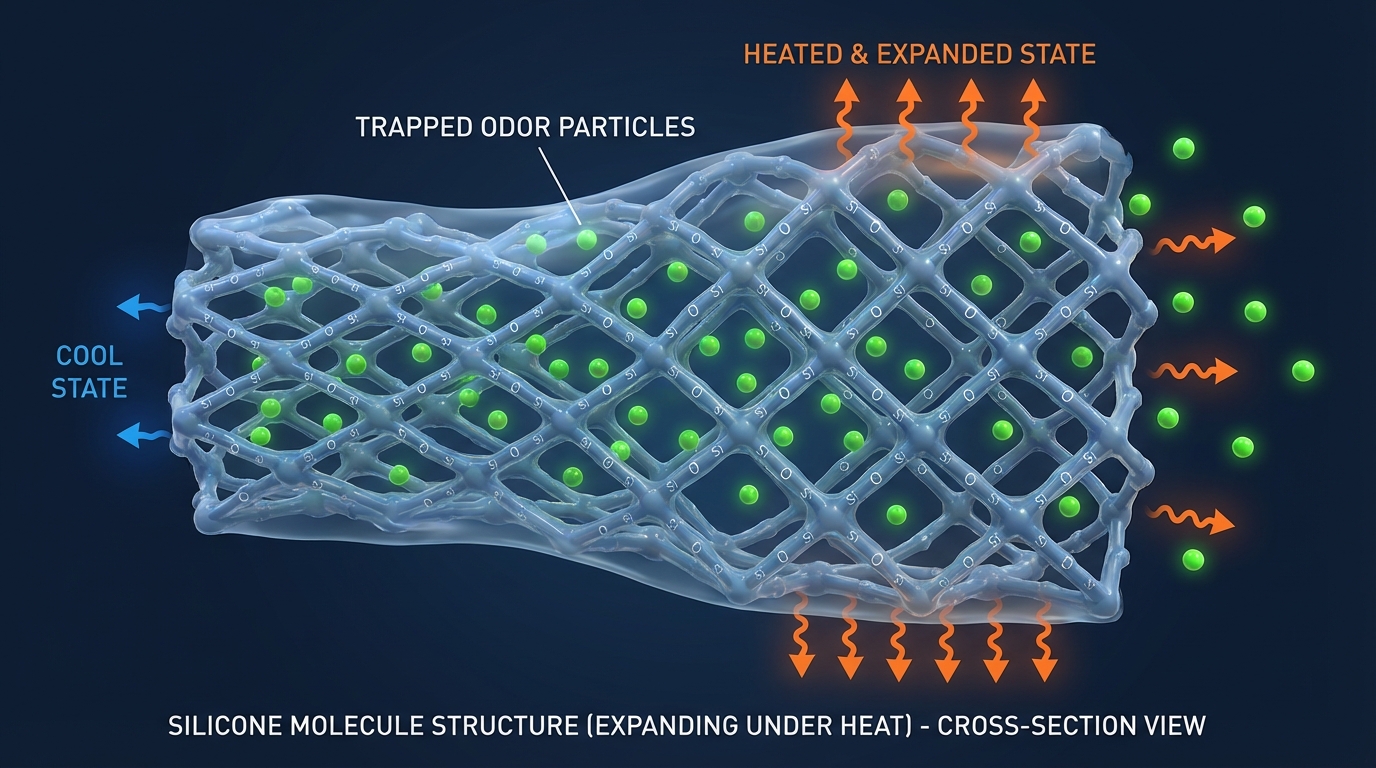

Understanding the molecular structure is the first step in learning how to get smells out of silicone. Silicone is a "breathable" polymer, meaning odors are not just sitting on the surface; they are actually trapped inside the molecular lattice. When you cook with pungent ingredients, the material's porous nature allows microscopic particles to settle deep within the structure.

Look at this:

- Silicone molecules expand when heated.

- Food oils migrate into these expanded gaps.

- The material "locks" the scent in as it cools.

- Porosity increases with lower-quality fillers.

The Molecular Expansion Theory

During the cooking process, heat causes the silicone matrix to widen significantly. This expansion creates an opening for volatile organic compounds and fats to enter the polymer chain. Once the heat source is removed, the molecules contract, effectively sealing those odor particles inside.

Porosity and Surface Retention

Silicone’s rubber-like consistency is naturally more prone to absorption than non-porous materials like glass or stainless steel. While the surface feels smooth, it contains microscopic peaks and valleys that hold onto residue. You must address the internal structure to achieve a truly clean result.

Key Takeaway: Silicone is a "breathable" polymer; odors aren't on the surface, they are trapped inside the molecular structure.

| Factor | Impact on Odor | Mechanism |

|---|---|---|

| Heat | High | Causes molecular expansion and oil trapping. |

| Porosity | Medium | Determines how deep particles can penetrate. |

| Material Age | Low | Older silicone may have more surface micro-tears. |

This table illustrates how physical properties contribute to the long-term retention of food scents within kitchen tools.

Is your silicone kitchenware 100% food-grade or filled?

Identifying the quality of your tools is essential when researching how to get smells out of silicone. Many cheaper products on the market contain plastic fillers that degrade more quickly and absorb odors aggressively. High-quality, pure silicone is significantly more resistant to permanent scent retention than these budget alternatives.

Think about it:

- Fillers reduce the thermal stability of the tool.

- Pure silicone maintains its molecular integrity longer.

- "Plastic-heavy" mixes trap scents permanently.

- High-grade materials are easier to deep clean.

Performing the "Twist Test"

You can easily check the purity of your kitchenware by performing the "Twist Test" at home. Simply take your silicone item and twist a section of it firmly between your hands. If white streaks appear in the creases, it indicates the presence of cheap fillers rather than 100% food-grade material.

Recognizing FDA-Approved Quality

Why does this matter? Premium products are manufactured to strict standards that minimize porosity and maximize durability. Choosing tools from silicone manufacturing experts ensures you are working with materials designed to withstand rigorous use without holding onto old flavors.

Key Takeaway: Poor quality silicone uses "fillers" that degrade and absorb scents more aggressively than 100% food-grade silicone.

| Material Type | Odor Resistance | Identification Method |

|---|---|---|

| 100% Food-Grade | High | Maintains color when twisted; FDA certified. |

| Silicone with Fillers | Low | Shows white streaks or powdery residue. |

| Medical-Grade | Very High | Most stable; least likely to leach or absorb. |

The difference in material purity directly dictates the effort required to neutralize stubborn odors after cooking.

How do you prepare silicone for deep cleaning?

Before you attempt advanced techniques, you must know how to get smells out of silicone starting with proper preparation. Removing surface grease is critical because external oils can act as a barrier to deep-cleaning agents. If the surface isn't pristine, your deodorizing efforts will only reach the top layer of the material.

Here is the kicker:

- Surface oils prevent "internal" cleaning.

- Abrasive tools create microscopic scratches.

- Hot water helps loosen surface-level debris.

- Preparation saves time during the baking phase.

The Initial Degreasing Wash

Start by using a high-quality grease-cutting dish soap and warm water to scrub the entire surface. Focus on crevices, such as the grooves in an Instant Pot gasket or the edges of a spatula. This step ensures that the subsequent heat or chemical treatments can penetrate the polymer pores.

Avoiding Harsh Abrasives

You should never use steel wool or rigid plastic scrubbers on your silicone tools. These abrasives create tiny tears in the surface that become new hiding spots for bacteria and odors. Stick to soft sponges or microfiber cloths to maintain the integrity of the food-grade surface.

Key Takeaway: Always remove surface residue first so the deep-cleaning agent can penetrate the polymer.

| Tool Type | Safety Level | Recommendation |

|---|---|---|

| Soft Sponge | High | Best for daily and prep cleaning. |

| Microfiber Cloth | High | Excellent for drying and polishing. |

| Steel Wool | Danger | Will ruin the silicone surface permanently. |

Proper preparation ensures that your chosen cleaning method has a clear path to the odor molecules trapped inside.

Can you bake smells out of silicone in the oven?

The most effective method for how to get smells out of silicone involves using your oven. Controlled heat forces the polymer to expand, allowing trapped oils to "sweat" out of the material where they can be washed away. This science-backed approach is the gold standard for professional chefs and home cooks alike.

Consider these steps:

- Heat the oven to a precise 250°F (120°C).

- Use a clean baking sheet for the items.

- Monitor for the characteristic "scent release."

- Allow for a cooling period before the final wash.

The 250°F (120°C) Method

Preheat your oven and place your dry, pre-washed silicone tools on a baking tray. Bake them for approximately 20 to 40 minutes depending on the intensity of the odor. This temperature is high enough to expand the molecules but low enough to prevent any damage to 100% food-grade silicone.

The Whiff Test Timing

How do you know when it's done? Carefully pull the tray out every 15 minutes and perform a "whiff test" to see if the smell has dissipated. Once the offending odor is gone, the silicone may actually smell slightly "hot" or neutral, indicating success.

Key Takeaway: Heat is the most effective "unlocking" mechanism for stubborn silicone odors.

| Temperature | Duration | Expected Result |

|---|---|---|

| 250°F (120°C) | 20-40 mins | Odors released via molecular expansion. |

| 300°F (150°C) | 10-15 mins | Faster results but higher risk of leaching. |

| 400°F+ | Never | Risk of melting or material degradation. |

Using controlled thermal energy is the fastest way to purge deep-seated scents that soaps cannot reach.

Does baking soda help remove odors from silicone gaskets?

When dealing with acidic odors like tomato sauce or vinegar, you need to know how to get smells out of silicone using chemistry. Baking soda is an alkaline base that works through a neutralizing reaction to pull scents out of the material. This is particularly effective for localized spots on spatulas or thin gaskets.

Ready for the secret?

- Baking soda creates a salt-forming reaction.

- It neutralizes organic acids on contact.

- A paste application increases contact time.

- It is 100% food-safe and non-toxic.

Neutralizing with a Base

Most food odors are slightly acidic, which is why a base like sodium bicarbonate is so effective. When the alkaline baking soda meets the acidic odor molecules, it neutralizes them into odorless salts. This chemical conversion is more efficient than simply trying to "mask" the scent with perfume.

Creating a Cleaning Paste

Mix baking soda with a small amount of water to create a thick, spreadable paste. Apply this generously to the affected areas and let it sit for at least two to four hours, or even overnight. This extended contact allows the base to draw out the deeper oils that are stuck near the surface.

Key Takeaway: Baking soda acts as a chemical neutralizer that pulls odors out through a "salt-forming" reaction.

| Application | Wait Time | Effectiveness |

|---|---|---|

| Dry Sprinkle | 12 hours | Moderate (best for storage). |

| Thick Paste | 4 hours | High (best for deep stains). |

| Soaking Solution | 2 hours | Good for large batches of tools. |

Baking soda provides a gentle yet powerful chemical alternative for those who prefer not to use heat for cleaning.

How do UV rays and fresh air eliminate persistent scents?

Nature offers a powerful solution for how to get smells out of silicone through solar energy. Ultraviolet (UV) rays from the sun have the ability to break down the chemical bonds of organic odor molecules. This method is completely free, passive, and incredibly effective for high-quality silicone tools.

Don't miss this:

- UV light breaks down organic compounds.

- Fresh air provides constant ventilation.

- Sunlight naturally sanitizes the surface.

- It is the most "green" method available.

The Power of Solar Neutralization

When you place your silicone kitchenware in direct sunlight, the UV radiation interacts with the trapped odors. This process, known as photodegradation, essentially "bleaches" the scents away at a molecular level. It is particularly effective for removing the smell of fermented foods or strong spices.

Ventilation and Open Space

Why is outdoor air better than a kitchen cupboard? Enclosed spaces trap the very gases the silicone is trying to release, often leading to re-absorption. Placing tools in a well-ventilated outdoor area ensures that as odors are released, they are immediately carried away by the wind.

Key Takeaway: Natural sunlight is a free, chemical-free way to sanitize and deodorize high-quality silicone.

| Condition | Odor Removal Speed | Benefit |

|---|---|---|

| Direct Sunlight | Fast | UV breakdown of molecules. |

| Shade/Breeze | Moderate | Ventilation and cooling. |

| Indoors/Drawer | Very Slow | No removal; likely re-absorption. |

Leveraging environmental factors like sunlight can refresh your tools without any manual scrubbing or energy costs.

Can odor-absorbing materials like charcoal rescue your kitchenware?

For items that cannot be heated or soaked, you can learn how to get smells out of silicone using dry absorbents. Materials like activated charcoal or coffee grounds have massive surface areas designed to trap airborne and contact molecules. This "dry soak" method is perfect for items with delicate components.

Here is the deal:

- Charcoal has a high internal surface area.

- Coffee grounds provide a natural masking effect.

- No moisture is required for this process.

- It is ideal for long-term storage maintenance.

Activated Charcoal and Coffee Grounds

Activated charcoal is specifically processed to have millions of tiny pores that capture gas-phase odors. Similarly, dry coffee grounds contain oils and carbon structures that can pull scents from nearby silicone surfaces. Simply place the tool in a sealed container with these materials for several days.

The 3-Day Extraction Method

Patience is the primary requirement for this technique to be successful. You should leave the silicone item submerged or enclosed with the absorbent material for at least 72 hours. This gives the molecules enough time to migrate out of the silicone and into the more "attractive" absorbent.

Key Takeaway: If heat isn't an option, use a "dry soak" in charcoal or clay-based cat litter.

| Absorbent | Best Use Case | Clean-up Effort |

|---|---|---|

| Activated Charcoal | Maximum odor removal | Low (use bags). |

| Coffee Grounds | Masking + Removal | Moderate (dusting). |

| Newspaper | Budget option | Low. |

Using dry extraction is a slow but steady way to refresh tools that might be sensitive to liquid soaks.

What role do gentle solvents and soaps play in odor removal?

Every professional knows how to get smells out of silicone involves using surfactants correctly. Dish soaps are designed to surround oil molecules and make them water-soluble so they can be rinsed away. Without a proper solvent, the oils you release via heat or baking soda will simply settle back into the silicone.

Why does this matter?

- Surfactants break the bond between oil and silicone.

- Soaking allows for deeper liquid penetration.

- Proper rinsing removes the "salts" formed by soda.

- It ensures a residue-free finish for the next meal.

Dishwashing Liquid as a Solvent

Standard dishwashing liquid contains powerful surfactants that lower the surface tension of water. This allows the water to get into the microscopic pores of the silicone more effectively. When used after a heat treatment, the soap quickly "grabs" the secreted oils before they can cool and re-trap.

The Soak Technique

For stubborn odors, a simple wash isn't enough; you need an extended soak in hot, soapy water. Submerging your tools for 30 to 60 minutes allows the detergent to work into the material's surface layers. This is often the final step needed to achieve a completely neutral scent.

Key Takeaway: A high-quality solvent (dish soap) is necessary to wash away the "salts" and oils released by other methods.

| Solvent Type | Strength | Best For |

|---|---|---|

| Dish Soap | Moderate | Daily grease and general odors. |

| Isopropyl Alcohol | High | Deep sterilization (use sparingly). |

| Boiling Water | High | Thermal expansion + rinsing. |

Solvents act as the transport mechanism that finally removes unwanted scent particles from your kitchen environment.

Are there risks to using high heat for cleaning silicone?

Safety is paramount when learning how to get smells out of silicone to avoid damaging your investment. While silicone is incredibly heat-resistant, exceeding its stable temperature threshold can lead to material degradation. You must balance the need for molecular expansion with the structural limits of the polymer.

Keep this in mind:

- Extreme heat can cause chemical leaching.

- Over-heating may lead to a tacky or sticky surface.

- Fillers in cheap silicone melt at lower temps.

- Precision is key for food-safe results.

Understanding Stability Limits

Most food-grade silicone is stable up to 450°F for cooking, but for cleaning, you should stay much lower. Keeping your oven at or below 250°F (120°C) provides plenty of expansion without approaching the "degradation zone." This ensures your tools remain supple and safe for years.

Preventing Chemical Leaching

If you use excessively high temperatures, you risk breaking the chemical bonds within the silicone itself. This can result in the leaching of siloxanes, which are not intended for heavy ingestion. Stick to the science-backed low-heat methods to keep your kitchen "green" and healthy.

Key Takeaway: Silicone is stable, but extreme heat can damage the integrity of the material and cause leaching.

| Temperature Range | Safety Level | Action |

|---|---|---|

| 200°F - 250°F | Very Safe | Ideal for deep cleaning. |

| 250°F - 350°F | Safe | Limits should be monitored closely. |

| Above 400°F | Risky | Avoid for cleaning purposes. |

Maintaining strict temperature control protects both your kitchen tools and the health of your family.

How can you prevent smells from returning to your silicone tools?

The ultimate goal in how to get smells out of silicone is to ensure the problem doesn't recur. Prevention is significantly easier than deep-cleaning a heavily saturated gasket or mat. By adopting a few professional habits, you can keep your premium tools smelling like new indefinitely.

Look at these tips:

- Rinse with cold water immediately after use.

- Use separate tools for "sweet" vs "savory."

- Store items in a dry, ventilated area.

- Invest in premium silicone products from the start.

Immediate Post-Cook Rinsing

As soon as you finish using a silicone tool, rinse it under cold water. While hot water opens the pores, cold water helps "close" them quickly, trapping fewer odors before you even get to the sink. This simple 5-second habit can reduce odor absorption by up to 50%.

Material Selection Matters

High-quality materials are the foundation of a fresh kitchen. Buying from a reputable food-grade silicone manufacturer means you are getting a product with fewer fillers and lower porosity. These tools naturally resist odors and last significantly longer than budget alternatives.

Key Takeaway: Prevention is easier than cure; wash items immediately after contact with pungent ingredients.

| Prevention Habit | Effort | Impact |

|---|---|---|

| Cold Water Rinse | Very Low | High (stops oil entry). |

| Dedicated Tools | Medium | Very High (prevents cross-contamination). |

| Proper Storage | Low | Moderate (stops stale smells). |

Implementing these small changes will ensure your silicone collection remains a versatile and odor-free asset in your culinary arsenal.

Frequently Asked Questions

Can I use bleach to clean silicone?

While bleach is a strong base, it is generally too harsh for food-contact silicone and can cause the material to become brittle or yellow over time. It is much safer and more effective to stick to baking soda or the low-heat oven method described above.

Why does my silicone smell like soap?

This typically occurs when dish detergent scents get trapped in the molecular gaps alongside food oils. To fix this, use the oven-bake method at 250°F to release the trapped soap molecules and oils, then rinse with plain hot water.

Is vinegar effective for removing silicone smells?

Vinegar is an acid, and because most food odors are also acidic, it usually won't create the necessary neutralizing reaction. You are better off using an alkaline base like baking soda to chemically counter the pungent scents.

Will the oven method melt my spatula?

As long as your tool is made of 100% food-grade silicone and you keep the oven at 250°F, it will not melt. Genuine silicone is incredibly stable and can withstand temperatures far higher than the cleaning threshold without losing its shape.

How often should I deep-clean my gaskets?

For high-odor tasks like fermenting or cooking with garlic and onions, a deep clean is recommended once a month. For general baking tools, a deep clean is only necessary when you notice a "lingering" scent that doesn't wash away with soap.

If you have more questions about maintaining your professional-grade tools, contact us today for expert guidance.